Kesalahan format email

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Berita

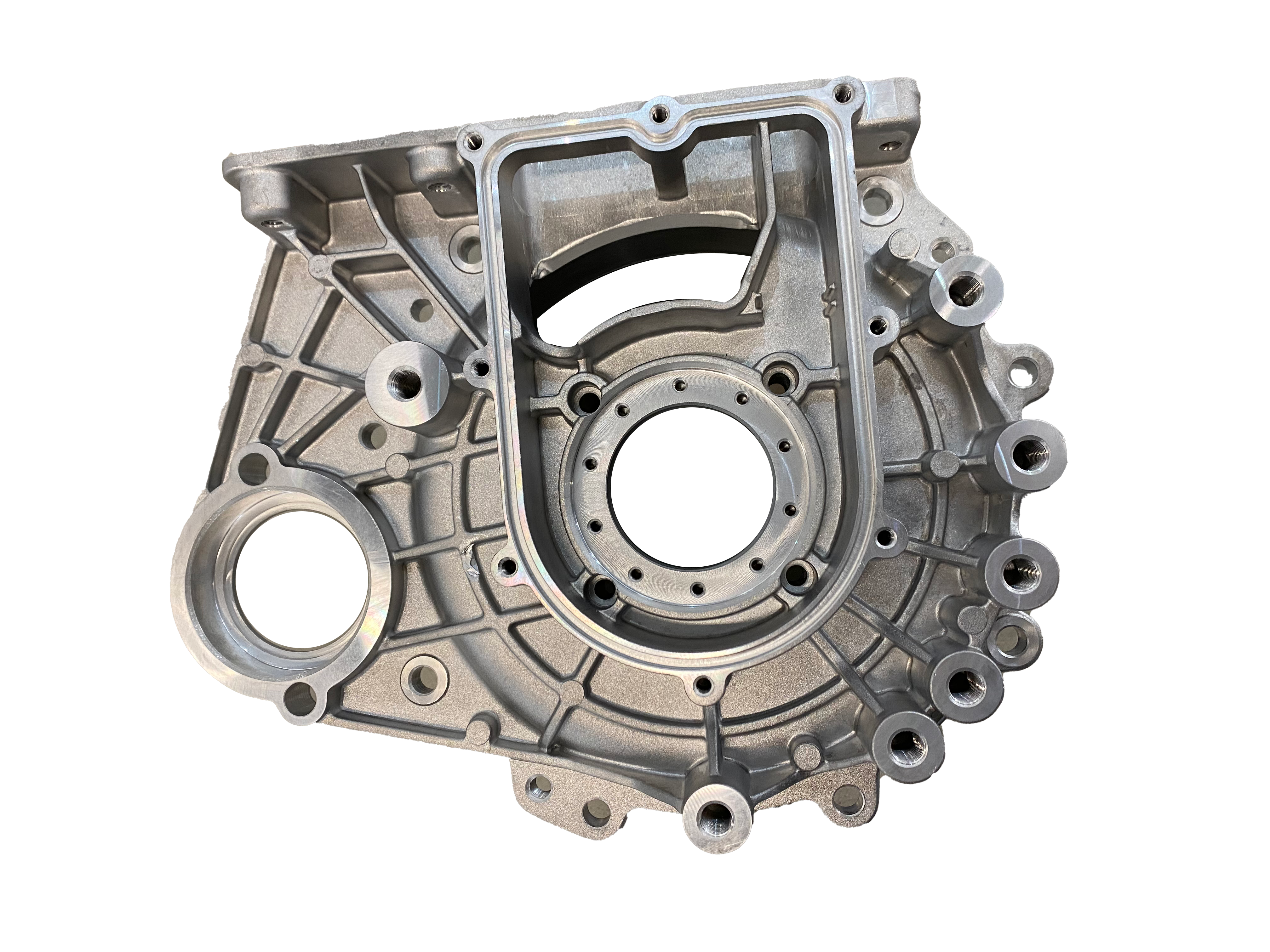

Several Major Processes of Zinc Alloy Die Casting

With the rapid development trend of social development, the aluminum die-casting manufacturing industry has also achieved a certain level of steady development. For zinc alloy die castings, many people think that it is not easy to feel unfamiliar. Many parts that must be used in industrial production are all made of zinc alloy materials for aluminum die casting production. Below, I will introduce the six major processes of the whole process of zinc alloy die casting in detail.

Several major processes of zinc alloy die casting

- First, to carry out zinc alloy die-casting, each standard value of the aluminum die-casting machine must be determined according to the basic parameters of the casting, and then the appropriate abrasive tools can be installed to start production.

- Second, in the case of aluminum die-casting, there are some burrs on the surface of the product. This burr is some metal material particles. This kind of metal material particles will make the surface of the casting look very rough, so it must be This particulate matter is removed.

- Third, if the product must have holes or buried holes, it must be applied to the tapping machine, and the tapping machine is used to connect the holes of the casting. This process can be omitted if there is no need.

- Fourth, the most important step in the development of zinc alloy die-casting is to carry out the grinding and polishing solution before the electroplating process and painting. Grinding and polishing are to make the metal surface of the castings smoother.

- Fifth, after grinding and polishing, once again carry out more delicate solutions to the surface of the casting, such as electroplating, painting, powder spraying, and laser marking. Now that the surface is solved, the casting is formed. Some castings can already be counted as finished products.

- Sixth, the last step is to carefully inspect all the castings. If there are no problems, they can be packaged and delivered.

Zinc alloy die-casting is probably the six processes above. If a zinc alloy die-casting manufacturer wants to do a good job of the product and wants to produce castings with good characteristics and good quality, then every process must be refined. If it is done finely, the quality of such castings will be more assured.

What are the unique advantages of zinc alloy die casting

What is the cost of zinc alloy die castings and aluminum alloy castings?

If the structure and casting process allow, it is more cost-effective to use aluminum alloy profiles. The proportion of zinc alloy materials is about 2.5 times that of aluminum alloy profiles, and the price is very high, so the raw material cost of zinc alloy materials is two or three times more expensive than that of aluminum alloy profiles. Nowadays, many companies want aluminum alloy profiles to replace zinc alloy materials in order to reduce costs, but some cannot be replaced, because the compressive strength, strength and formability of zinc alloy materials are much better than aluminum alloy profiles.

The best solution for the clamping line of zinc alloy die-casting products?

The high efficiency and low efficiency of hand-made production, but this can be very easy to comply with the regulations, and it is not easy to be extravagant and wasteful. Grinding with a sand wheel is very easy to quote. It is also possible to turn on the abrasive tool again, which is the best.

What is the difference between hot-dip galvanized aluminum alloy and aluminum die-cast zinc alloy material?

Working pressure forging is a way of filling a die with liquid metal under working pressure to produce castings. Hot-dip galvanizing is a method of infiltrating raw materials such as steel frame structural products in batches, and obtaining hot-dip galvanized parts from a zinc bath.

Conclusion

For more information about 6063 aluminum die casting,custom die casting manufacturers,gravity die casting supplier, we are glad to answer for you.