Kesalahan format email

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Berita

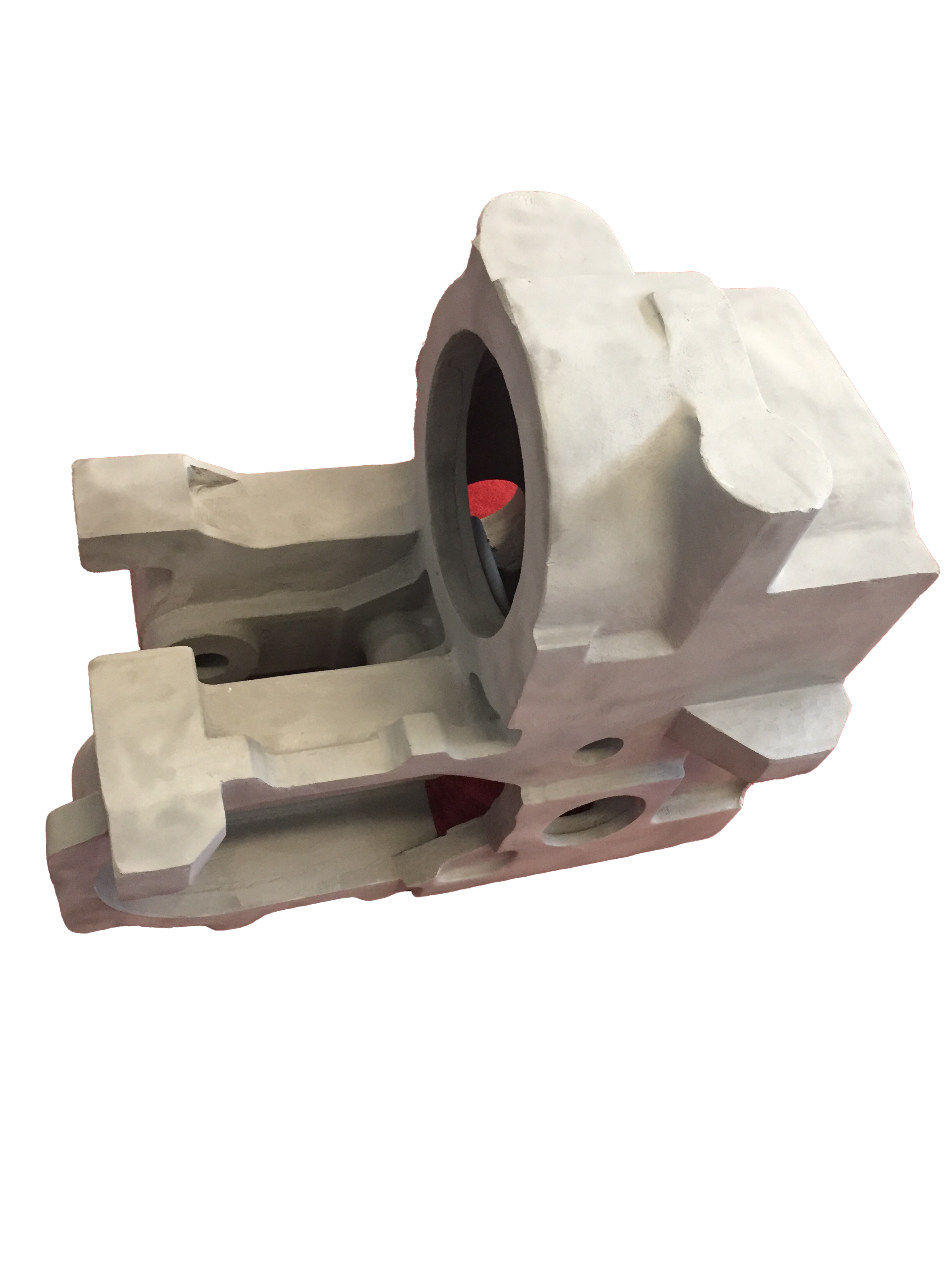

Some Methods of Surface Treatment of Die Castings

The quenching and tempering treatment of aluminum alloy castings refers to changing the mechanism of the aluminum alloy by manipulating the heating temperature, thermal insulation time and cooling rate according to a certain quenching and tempering treatment standard. The key purpose is to improve physical properties and improve corrosion resistance. performance, improved production processing characteristics, and reliability of specifications. The heat treatment methods of aluminum alloy castings can be divided into the following four categories:

Some methods of surface treatment of die castings

Annealing treatment:

The aluminum alloy castings are heated to a higher temperature, generally around 300°C. After a certain period of thermal insulation, the process of cooling with the furnace to the indoor temperature is called quenching. During the whole process of quenching, the solid solution is dissolved and the phase particles are aggregated, which can remove the thermal stress of the casting, stabilize the size of the casting, reduce the deformation, and expand the plastic deformation of the casting.

Aging treatment:

The castings are heated to the highest possible temperature, close to the melting point of eutectic crystallization, maintained at this temperature for a long time, and then rapidly refrigerated to maximize the melting of the strengthening components. The high temperature condition is fixed and stored to the indoor temperature, and the whole process is called aging treatment. Aging treatment can improve the compressive strength and plastic deformation of castings, and improve the corrosion resistance of aluminum alloys. The key to the actual effect of aging treatment lies in the following three elements:

Aging treatment temperature.

The higher the temperature, the faster the melting rate of the strengthening element, and the better the actual effect of strengthening. Generally, the limit of the heating temperature is less than the initial coarse grain temperature of the aluminum alloy, and the lower limit of the heating temperature should be as much as possible to be integrated into the solid solution by strengthening the components. In order to obtain a good actual effect of solid solution strengthening, but it is troublesome for the coarse grains of aluminum alloys, sometimes the method of grade classification and heating is used, that is, heat insulation at a low melting point eutectic temperature, so that after the components are diffused and melted outside, low temperature can be achieved. There will be no melting point eutectic, and then the temperature is raised to a higher temperature to carry out thermal insulation and heat treatment. During the aging treatment, it should also be noted that the heating rate is not suitable for too fast, so as to prevent the deformation of the casting and the melting of the partially agglomerated low melting point mechanism, resulting in coarse grains. The migration time of the haggard fire in heat treatment, tempering and tempering treatment should be as short as possible, generally not exceeding 15s, in order to prevent the external diffusion and dissolution of aluminum alloy elements and reduce the characteristics of aluminum alloy.

Thermal insulation time.

The thermal insulation time is determined by the melting rate of the reinforcing element, which depends on the type of aluminum alloy, composition, structure, forging method, and the appearance and wall thickness of the casting. The thermal insulation time of aluminum alloy casting is longer than that of deformed aluminum alloy profiles. Generally, it is clarified by experiments. Compared with the same type of metal mold castings, general sand mold castings should increase by 20%-25%.

Cooling rate.

The greater the cooling rate given to the casting during heat treatment, the higher the over-contrast of the solid solution stored from the high temperature condition, and the higher the physical properties of the casting, but the greater the thermal stress generated, the higher the casting. The probability of deformation is also greater. The cooling rate can be changed according to the use of cooling substances with different thermal conductivity, heat transfer, heat of volatilization and viscosity, in order to obtain small thermal stress, castings can be used in hot substances (boiling water, boiling oil or melting). refrigerated in salt).

In order to ensure that the castings have high physical properties and low thermal stress after heat treatment, isothermal heat treatment is sometimes used, that is, the aging-treated castings are quenched into a thermal material of 200-250 ° C for thermal insulation. Set time, integrate aging treatment and cold working.

Conclusion

For more information about a356 aluminum die casting,pressure die casting cost estimation,shield aluminium die casting, we are glad to answer for you.